Сведения о компании

Shijiazhuang Bang dong Pipeline Technology Co,Ltd.

- [Hebei,China]

- Деловой Тип :производитель

- Основные рынки: Африка , Азия , Восточная Европа , Европа , средний Восток , Северная Европа , Западная Европа

- Экспортер:91% - 100%

- Certs:CE, ISO9001

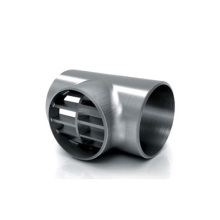

- Описание:A420 Wpl6 Carbon Steel SR Elbow,90 Reducing Elbow In Different Od,Hot Induction Pipe Elbow Bend